Service and Installations

BCS maintains the only fully trained and equipped service crew in the Northwest to service Wheelabrator and all brands of shot blast, air blast cleaning and shot peening systems. Our crews are certified in safe working practices, confined space entry, fall protection etc. Our service personnel are some of the most experienced in the country in the installation and service of blast cleaning and shot peening systems. We are equiped for field fabrication, heavy rigging, vent pipe design and installation and service for your blast equipment.

BCS is an authorized Warranty center for Wheelabrator.

BCS has established a solid reputation for completing work on time and with the quality required for production machinery. We specialize in "shut down" jobs that have a critical time schedule.

BCS offers simple repairs, tune-ups, service inspections, maintenance and upgrades to new components to keep your machinery as productive as possible.

Bradken Smoke Collection System

T Bailey Machinery Move

Brooklyn Iron Rebuild

Setina Wheelabrator Spinner Hanger

Genie Installation

Precision Cast Parts, Portland, OR

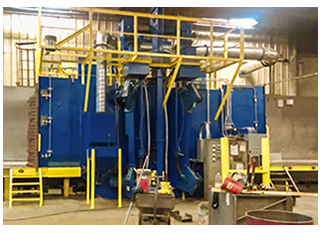

We installed a 12' X 12' X 20' FULL SCREW FLOOR RECLAIM

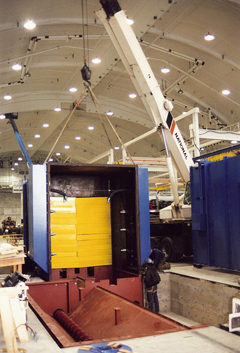

Electric Boat, Dual Media Blastroom

This Blastroom uses garnet and steel grit abrasives then seperates them back to

their respective hoppers, 150 feet per minute ventillation,

full screw floor and rubber lining.