Service and Installations

Case History of 2019 Bradken State of The Art Smoke Collection System

In 2018 Bradken Foundry in Tacoma Washington contacted Air-Tek NW to begin designing a

state of the art Dust and Smoke Collection System.

The system would consist of custom designed and built booth enclosures where operations would air arc, torch cut, weld

and grind large castings. These castings are moved by overhead bridge cranes. So crane access slots that could open

and close needed to be part of the booth design. Much care and design work went into how each booth would be

ventilated including computer modeling of the air flow patterns.

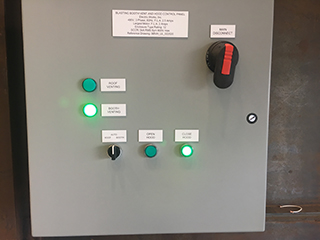

When one of the booths is open for load and unload, the system includes automated butterfly gates in the vent piping to

pull air from the ceiling of the building during these times. Once a casting is loaded in and the crane slot door and work

doors are closed the ventilation switches back to pulling air through the booth. The electronic controls for this

were

supplied by Air-Tek.

The space available for the dust collectors was very limited. So the collectors were installed on a raised platform with

the fans on the ground. This allows dust to be transferred to super sacks for disposal.

The design and building of the booths was done by Argo Blower in Seattle WA as part of the overall package that Air-Tek

supplied to Bradken. Argo also designed, built and installed them including the custom made roof slot doors with chain

drives. Argo also installed the "dirty side" vent pipe to connect each source to the collectors. Argo also built and

installed the exhaust stacks.

In addition to the smoke collection theer is a car table style blast cleaning machine built by Blast Cleaning Technologies of

West Allis, Wisconsin. The North Torit collects from it and 2 booths. The south Torit collects from the other 3

booths. Each is a model DFE -5-120 with 125 HP blowers controlled with Variable Speed Drive and air flow controller so

the same air colume is delivered every day and energy efficiency is assured. Complete control Panels for each were

supplied by Torit.

The ventillation smoke and fume from the castings has the potential to include some toxic metal compounds depending

on the casting. So air that is filtered through the Torit Donaldson cartridge style dust collectors is filtered again through

HEPA air filters to assure that only clean air is exhausted through the stacks which are tested and monitored.

The installation of the machinery as well as trouble shooting, operator training and commissioning was completed by

June of 2019. The Air-Tek crew unloaded and assembled the new machinery from Torit and worked in support of

Bradken and Argo to provide the completed system that Bradken required.

| MACHINERY INSTALLATION > |  |

|

|

BUTTERFLY VALVES IN THE DUCTING TO EACH BOOTH IS VENTED WHEN THE DOORS ARE CLOSED. CEILING IS VENTED WHEN DOORS ARE OPEN > |

|

|

|

|

| CRANE SLOT DOOR OPENING VIDEO |  |

TWO TORIT DFW-5-120 CARTRIDGE STYLE DUST COLLECTORS WITH 125 HP BLOWERS HEPA AFTERFILTER AND VARIABLE SPEED FANS < EXHAUST STACKS |

|

< BLAST MACHINE VENTED WITH |

CRANE SLOT DOOR CLOSING VIDEO |